Leab Six Sigma - The innovative Six Sigma method incorporates data-driven, statistics-based tools and techniques designed to facilitate lean manufacturing, better process management, and continuous improvement.

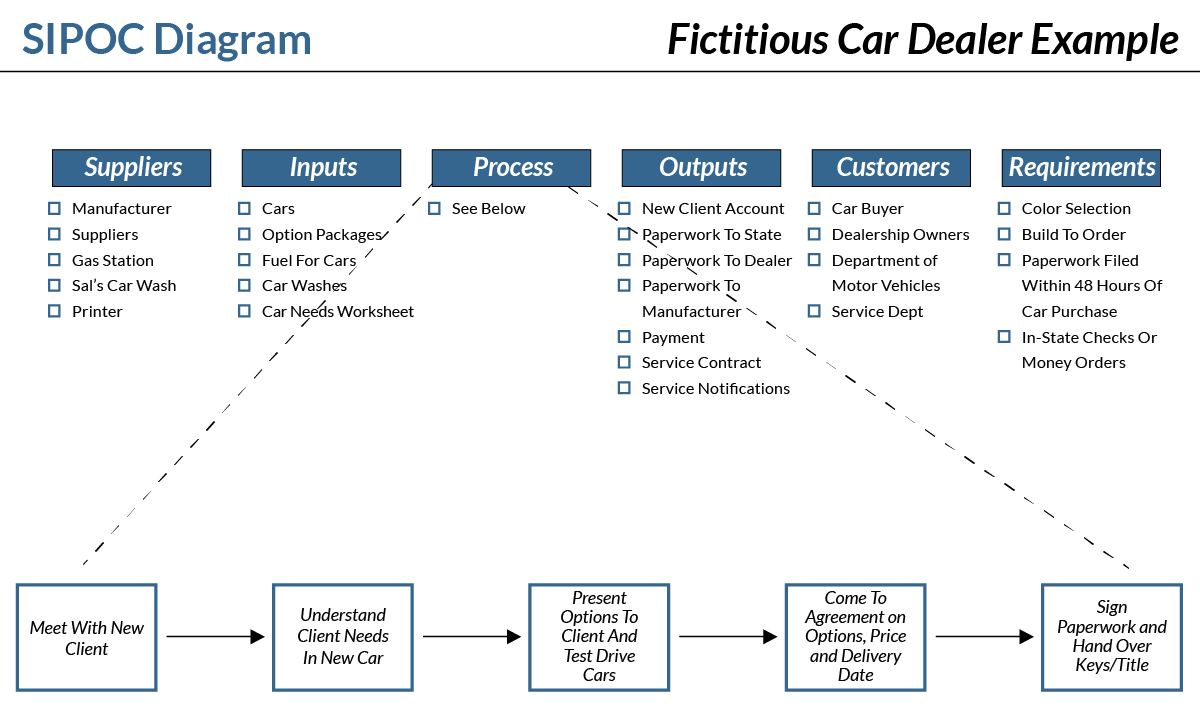

The SIPOC model is a part of the Six Sigma methodology. In process improvement, a SIPOC is a tool that summarizes the inputs and outputs of one or more processes in table form. It is used to define a business process from beginning to end before work begins. The acronym SIPOC stands for suppliers, inputs, process, outputs, and customers which form the columns of the table. Wikipedia

Difference between Process map and SIPOC : The tool is called “High Level Process Map” because, unlike other processes wherein we put every requirement of the process and also more detailing is done, SIPOC only offers the brief level of information in form of Suppliers, Input, Process, Output and Customers.

Click here for Seven basic Quality Tools

Six Sigma was developed with a very specific goal: reduce variation and defect rates in production processes through statistical analysis. To do this, Six Sigma uses one of two, 5-step approaches – either the DMAIC or the DMADV method.

The Lean method, on the other hand, is entirely focused on eliminating waste, providing maximum value to customers with the lowest possible amount of investment.

No comments:

Post a Comment